What Is Earthing? | What Is Electrical Earthing System?

Earthing is meant to be carried out by digging 2.5 to 3 meters deep into the ground, to make a pipe or plate piece of copper or galvanized iron in it.

Or The Direct Connection Of The Metal Body Of The Electrical Device To The Ground Through The Integrity Wire Is Called Earthing System . Which Is Also Called Grounding.

Indian Electricity Rules To Any Metalliferous Body Of Every Tool In Electrical Installation 1956 Earthing Is Mandatory.

The Reason Is That The Circuit Acts As A Safely Device Like Fuse In The Circuit .

Similarly, Earthing Also Acts As A Protective Tool For That Installation And The Person Working On That Installation. Below Are Some Of The Main Reasons Why Earthing Is Very Important. Importance Of Earthing

| Read Also... |

Human Life Should Be Protected From Electric Shock.

Power Generators, Alternators And Power Distributing Transformers Are Paired With Neutral Earthing.

The Ground Is A Conductor Of Electricity. When The Phase Wire Or Positive Conductor Of The Supply Is In Contact With The Body Of The Electrical Device, An Electric Current Starts Flowing In The Body Of That Device.

If Work On The Stand At A Man On The Ground In This Case That Device, The Contact Flow In The Body Of The Device Current Is.

And That Person Feels Electric Shock .

If The Body Of The Device Is Connected To The Wire. Then The Phase And Earthing Are In Contact.

The Circuit Of The Instrument Is Converted Into A Short Circuit . Due To The Circuit Short Of That Device, More Current Flows In It.

That Current Also Flows Through The Fuse Installed In That Circuit. As A Result, The Fuse Wire Of That Fuse Breaks Due To Excessive Current.

The Circuit Of That Device Turns Into An Open Circuit . And Thus Further Potential Living And Finance Losses Are Avoided.

To Protect Equipment Or Installation Due To Leakage Current.

If The Insulation Of A Wire Or Cable Is Of Low Capacity, Then Later Its Insulation Resistance Capacity Decreases Further . Due To This, Leakage Current Flows From The Insulation Of The Wire Or Cable, Which Keeps Coming In And Moving In The Metal Body Of The Device.

This Causes The Body Of The Device To Become Hot. If There Is More Leakage Current Then The Body Becomes More Hot. Winding Of The Device Is Likely To Cause Burns Due To The High Temperature. Bearing May Be Defective.

If The Device Is Connected To The Earthing System In This Situation, Then Leakage Current Runs Through The Ground Through The Wire. And The Ill-Effects Occurring Are Averted.

To Protect The Sky-High Buildings, Large Electrical Equipment And Over Head Lines.

Overhead Line, Genrating Station, Substation And High-Rise Buildings, If All The Lightning Falls, They Can All Be Destroyed By Burning. Therefore, On High Buildings, Earth Conductor And Over Head Line Are Attached To The Earthing System By Placing Lightning Arrester On It . Sky Electricity Enters The Ground Through The Earth Conductor. And Thus Because Of Earthing All These Are Safe.

What Is The Difference Between Neutral And Earthing?

From The Above Mentioned Findings, It Proves That The Earthing System Is A Means Of Protection. Reason: Neutral Located In The Circuit Completes The Path Of Current Flowing In The Circuit.

So Earthing Completes The Path Of Leakage Current. Neutral Is A Caste Associated With Load Resistance , So The Earthing Device Is Attached To A Metalized Body.

Neutral This Circuit Is Used For Closing And For The Return Path Of Current, Then Earthing Is Used As A Means Of Protection To Leak Leakage Current.

Earthing At These Places Is Very Important When Using Electricity.

- All Switches, Distribution Box, Busbar Chambers With Metal Body To Their Body.

- Electric Motor, Transformer His Body At Least 2 Places.

- Electric Iron, Heater, Geezer, Cooler’s Body.

- Big Long Terminal Of Tree Pin Socket.

- Star Point In The Three Phase Four Wire System.

- Neutral Conductor In DC Three Wire System.

- Underground Cable Armoring.

- Every Metal Conduit In Conduit Wiring.

- And According To Indian Electricity Rule 90, The Pole Of The Over Head Wire Should Be Earthing At Least 4 Places Every 1.6 KM.

Earthing System Rules Of ISI On The Subject (ISI Rules Regarding Earthing)

- Outside Of Any Building, Earthing Should Be Done At A Distance Of 1.5 Meters From The Building.

- Earth Electrode And Earth Conductor, Nut-Bolt And Washers Should All Be Of The Same Metal.

- Earth Conductor Should Have Twice The Current Current Carrying Capacity Of The Circuit.

- The Mean Conductor Size Of Any Circuit Should Not Be Less Than 14 SWG. The Main Means Conductor Shall Not Be Less Than 8 SWG.

- The Mechanical Conductor Of The Earthing System Should Not Cause Mechanical Damage, So It Should Reach 60cm Below The Ground Where It Is Required Through A 12mm Diameter Pipe.

- Salt, Sand And Coal Should Be Laid Layer By Layer At An Interval Of 15-15 Cm Around The Earth Electrode.

- Earth Conductors Should Be Used Only With The Help Of Joint Nut-Bolt And Washers. And Soldering On That Joint Later

- Resistance Of Earthing Should Always Be Minimal. Earth Conductor Should Not Be More Than 1 Ohm If It Is Of Copper And 3 Ohm If It Is Of GI.

- In Order To Reduce The Earth Resistance During The Summer Days, Water Should Be Poured In The Funnel In Between.

Any electrical device that has a metallic body. Earthing is very important to that. It is very necessary to do Earthing in every home office building. How is earthing done? We are going to read this article today.

Earthing is very important in every electrical installation. But how is this Earthing done? In this article, we have explained closely.

What are the four types of earthing?

Mainly 2 types of earthing are done

- Plate Earthing

- Pipe Earthing

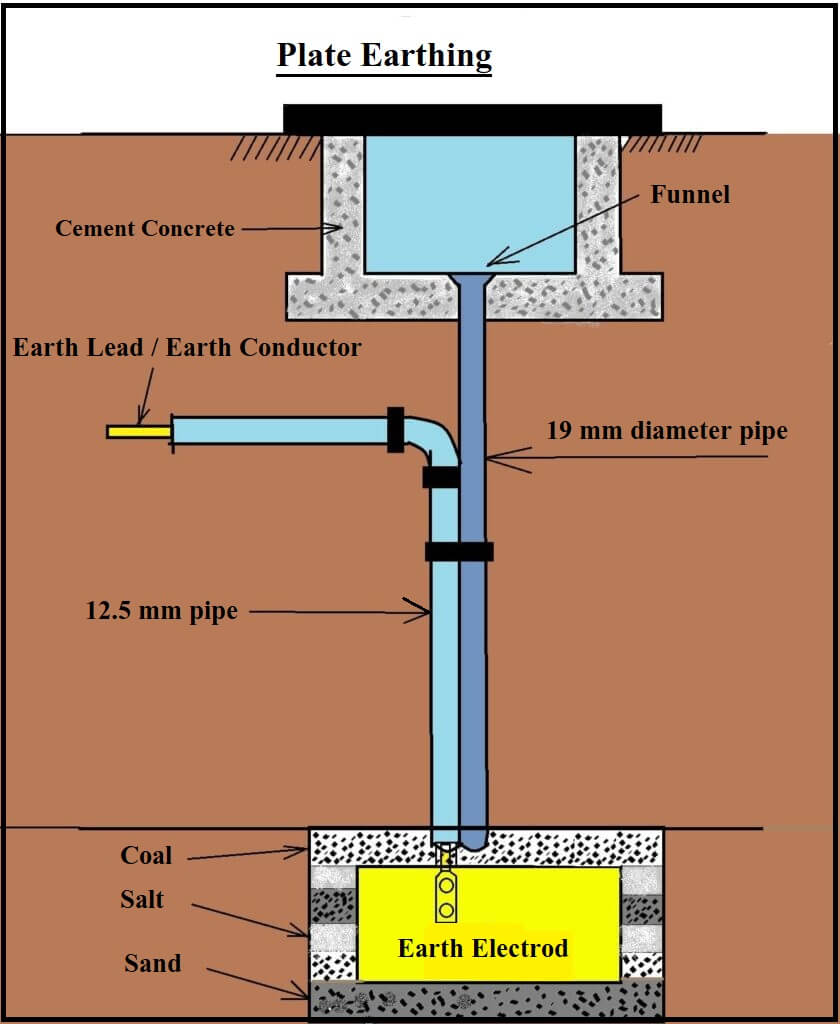

how to do plate earthing?

From the name of this type of earthing, we can understand that metal plates are used in it. For plate earthing, copper metal or G.I. key plate is used.

For plate earthing, a 90×90 cm pit is dug up to 3 meters deep in the ground.

What is the thickness of earthing plate?

In that pit 60 cm long × 60 cm wide and 3.15 mm thick copper plate or 60 cm long × 60 cm wide and 6.3 mm thick G.I. The key plate is used as the earth electrode.

Two pipes of diameter 19 mm and 12.7 mm are attached to that plate. A funnel is attached to the upper end of a pipe of diameter 19 mm. One open copper/G.I. The wire is brought out of the ground through a pipe with a diameter of 12.7 mm.

Sand (sand), salt and coal are spread around the earth electrode one layer after another of 15-15 cm. This type of layer is laid up to 90 cm.

After filling the rest of the pit with black soil, normally after 2.5 meters the pipe with earth conductor comes out, where earthing connection is to be done. The pipe which has a funnel on its upper end.

Around that pipe, a 30 cm × 30 cm cement concrete tank is made below the ground level, and it is covered with a lid made of cast iron.

In this way earthing is done by earthing the main switch and earthing conductor from there to the required place.

This type of earthing is done in generating stations and sub-stations. and for huse wiring.

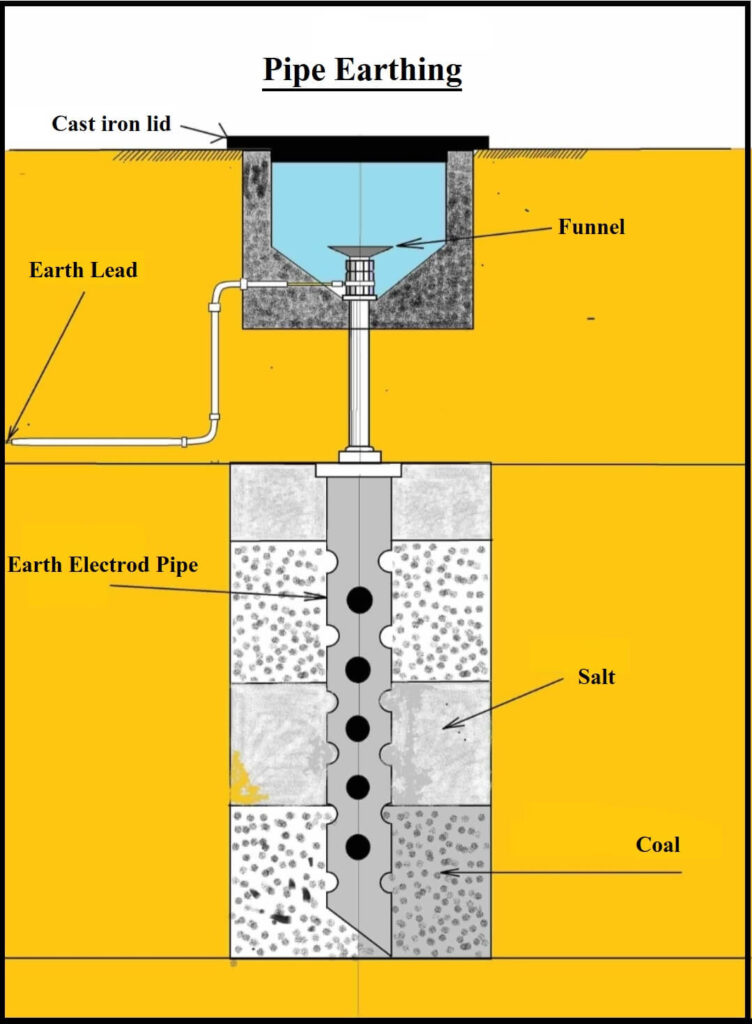

how to do pipe earthing?

For pipe earthing, a pit 70 cm long, 70 cm wide and 3.75 m deep is made in the ground. 38mm in diameter and 2 meters long a G.I. The pipe is used as earth electrode in that pit.

Holes of 12 mm are made on the entire surface of that pipe. Which are made at a distance of 7.5 cm among themselves. Connect this earth electrode with the help of reducing socket, one of 19mm diameter and one of 12.7mm diameter in two such G.I. Pipes are connected.

A funnel is attached to the upper end of a pipe of diameter 19 mm. Funnels are used to water the earthing. An open conductor earth electrode is connected to the earth lead and brought out through a pipe of 12.7 mm diameter.

Its purpose is that the earth lid should not be damaged from anywhere.

Layer by layer of sand (sand), lime and coal are spread around the earth electrode at an interval of 15-15 cm from the bottom.

The pit above the earth electrode is covered with soil.

The earth conductor, which is taken out of the 12.7 mm diameter pipe, is forwarded to the place where earthing is to be done, through 60 cm below the ground.

A cement concrete tank of size 30×30 cm is made around the funnel. It is covered with a cast iron lid.

This type of wiring is done for low and medium voltage installations.

Why are coal and salt used for earthing?

While earthing, salt and coal are poured around the earth electrode. Because salt absorbs the alkali of the ground. And coal keeps the soil moist. Due to which the conductivity of the ground increases. The conductivity of the ground will be high only then the leakage current will easily go into the ground.

Why is water put in earthing?

The land dries up during the summer season. Due to which the conductivity of Jamim decreases. To increase the moisture in the ground, water is poured through funnels in the earthing. A cast iron cover is placed on the funnel of earthing so that the way of pouring water into the earthing is not blocked.

You should also read this

| Home Page | Click here |

| Electrical Theory | Click here |

| Earthing | Click here |

| Electrical Equipment | Click here |

| Free Electrical Training | Click here |

| Transformer | Click here |